The PeACE Vest

Aim

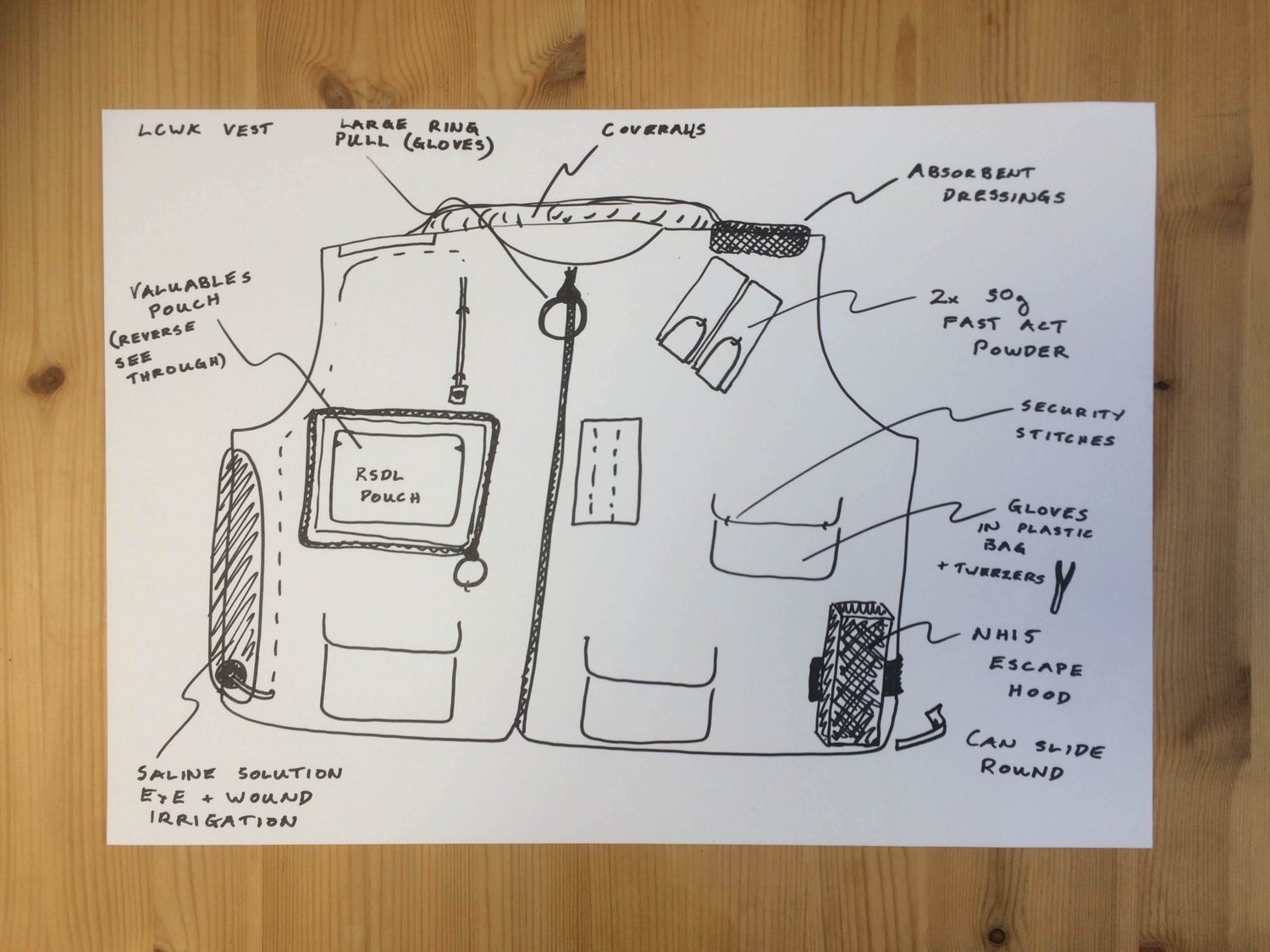

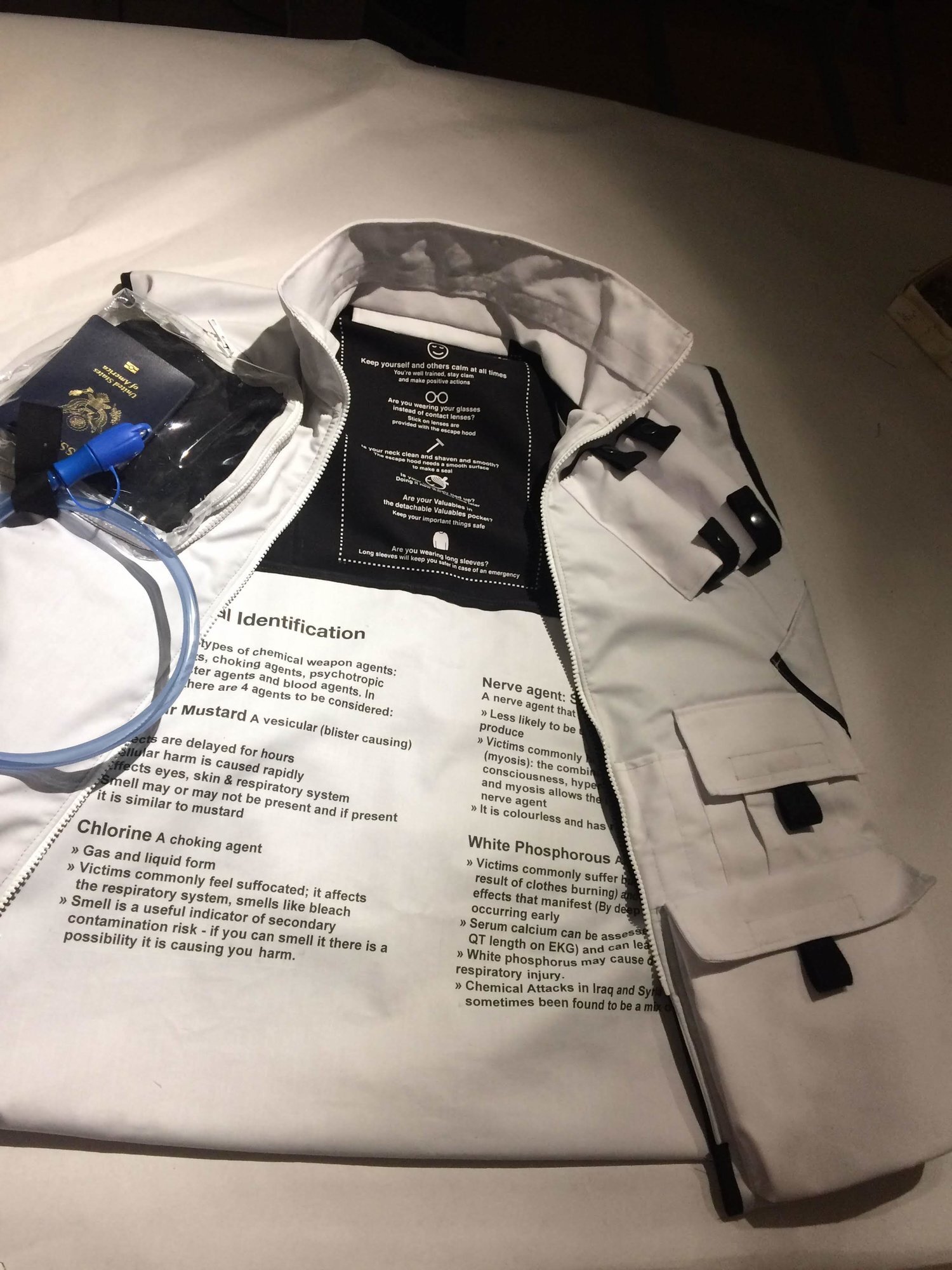

The PeACE Vest is an evacuation kit designed to be worn in areas where the threat of contamination from chemicals has been identified in areas where MSF works. The Vest was designed to make the process of personal decontamination simple and user friendly, in order to reduce the ‘fear factor’ often associated with the subject.

Throughout MSF’s history, teams are sometimes confronted with the threat of chemical warfare. This threat presents itself very rarely, and when it does, a great deal of work goes into risk mitigation and contingency plans. One of the contingency plans that exists is a decontamination kit in the form of a backpack, that users carry with them while working in ‘at risk’ areas. These kits are heavy, bulky, and – without repeated training - complicated to use. The backpacks sometimes cause more anxiety than relief and are often not on the person while they work.

The PeACE Vest aims to make a sometimes complicated procedure, as simple and user friendly as possible. The kit was designed to be worn and therefore to be always conveniently located. The kit aims to allow MSF staff to concentrate on their work, rather than worry about a security issue. And careful design and instructions on the inside, mean that the training to use the kit can be largely self taught and refreshed whenever is convenient.

One of the fundamental design principles of the PeACE Vest is lean design. Lean is an engineering technique developed in the automotive industry, and can be applied to any process in order to make it more efficient. Lean reduces waste, mistake proofs complicated systems, and enforces continual improvement, making the methodology a perfect fit for chemical decontamination.

When the project first began with the Sapling Nursery Fund (Internal MSF Innovation Fund) in MSF London in 2018, the team consisted of 1 returning logistician field worker with a problem. Now the team consists of world leading experts in the field, many talented designers, a manufacturer, training specialists, and still that original logistician. After almost 2 years the Vest will be available to go back to the field as a finished product, complete with a training module and user manual.

Status

Initiation

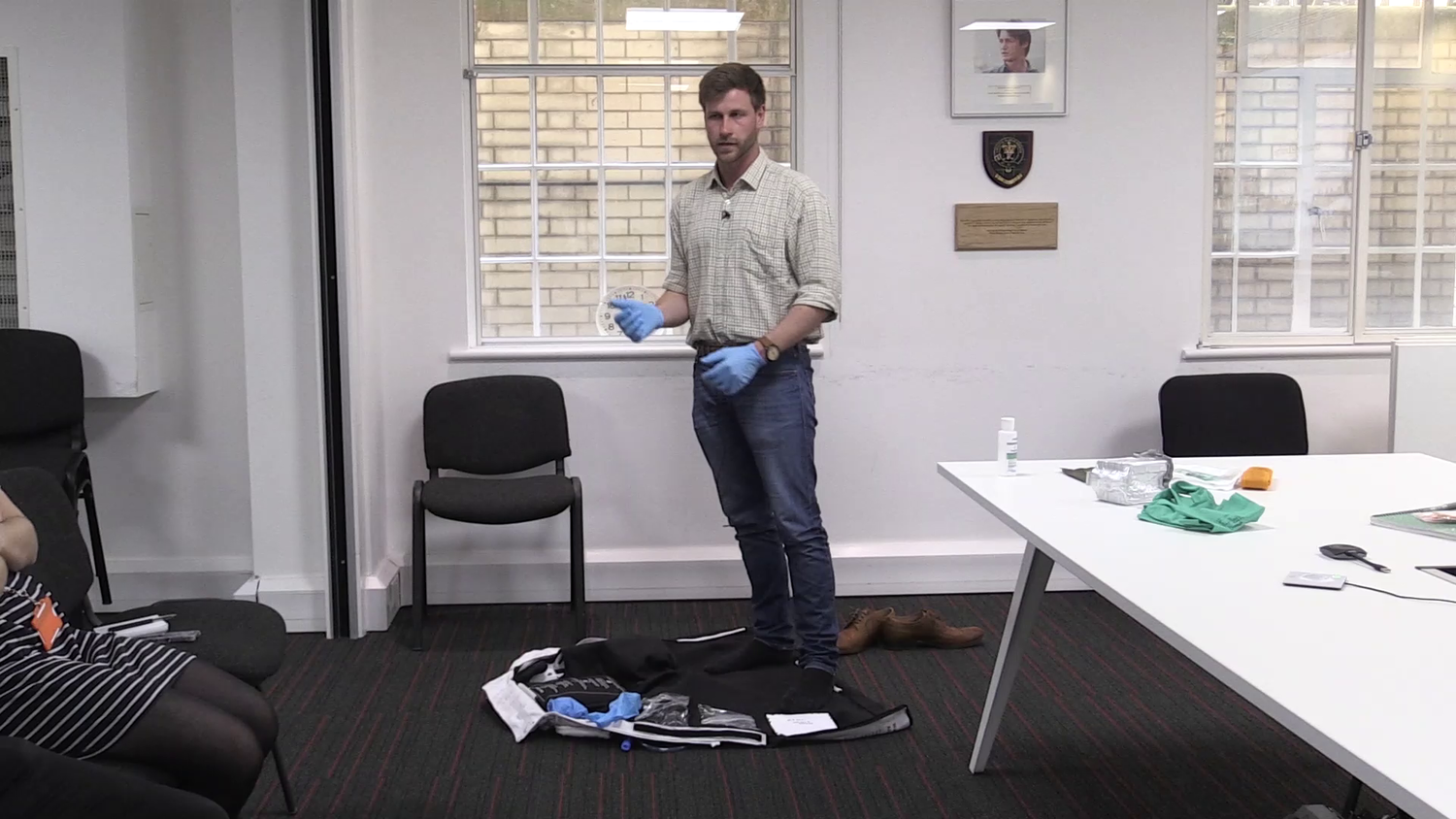

The first phase of the project resulted in a successful proof of concept prototype. The prototype gave the wider MSF community the chance to not only see a feasible solution, but to also gain a better understanding of what it must be like in the field with the current setup.

Development

The second stage of the PeACE Vest Development was funded and supported by the Sweden Innovation Unit, and turned a proof of concept into a product ready for MSF to buy. The pool of experts and collaborators grew, helping the team to use the latest and most up to date best practices, ensuring the right problem had been solved in the right way. At the end of the development stage, the root cause of the issue was questioned once again ‘is this innovation helping MSF to deliver medical care where it is needed most?’

Implementation

The final stage of the PeACE Vest as an innovation project was to complete production of the first order of kits, which was placed by the Operational Centre Amsterdam. The first commercial order will have been completed within 2 years of initial funding from MSF, and will mark the end of the formal development of the kit. The future of the PeACE Vest will be in the hands of a European manufacturing company and supplier, and will undergo continual improvement as the vest meets changing contexts in the field over the future.

The PeACE Vest has not only solved an important problem in the field, but has also gathered together and built a large support network for MSF to use in the future if it is ever needed.

Special thanks to those who have worked on and supported the project, especially from the beginning. We hope the kit will never need to be used in reality, and that in the meantime, the dedicated MSF teams around the world can continue their work with a little less worry on their shoulders.

“In one year we have achieved what most people would have thought the impossible, but isn’t that what MSF does?”

— ROGER MORTON, CASE LEADER

Resources

SCI DEV NET, ‘AID WORKER INVENTS VEST WITH BUILT-IN CHEMICALS PROTECTION’

Introducing the Protection Against Chemical Exposure (PeACE) Kit

Stakeholders

Operational Centre Amsterdam (OCA), Case Owner

MSF Sweden Innovation Unit, Case Manager

Funding

MSF SAPLING NURSERY FUND

Swedish Innovation Unit

Contact

ROGER MORTON, Case Manager, MSF Sweden Innovation Unit